What's Killing My Wire Rope? An investigation into wire rope failure.

Andrew T. Litecky

Welcome to The Hoist Guy's Blog, where our resident Hoist Guy, Andrew T. Litecky, shares his knowledge and experience of many years in the overhead material handling industry. This time to talk wire rope hoists and share a case study where the wire rope component was repeatedly experiencing premature wear.

Wire Rope Hoist Rope Damage

A customer recently contacted us to reorder the wire rope component of their Electrolift twin hook monorail hoist. While the hoist was only a year old, they had replaced the wire rope twice within six months. They sent a picture of the damaged rope and asked for reasons why the wire rope was failing.

What’s killing my wire rope?

It’s important to note that the wire rope used for hoists and overhead cranes is specially made of extra flexible Improved Plow Steel (IPS). It’s considered superior in durability and tensile strength (bending) to standard, everyday wire rope.

When properly sized and lubricated, a wire rope should last for years, even with frequent use. Wire rope hoists are recommended for heavy duty applications, high frequency usage and where long lifts are needed. So what was causing this wire rope to wear out so frequently?

The Answer

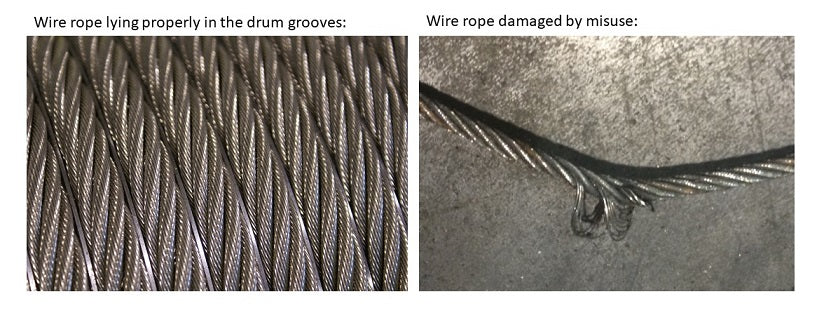

Most likely, there’s a problem with how the hoist is operated. Wire rope failure is almost always due to operator error. By design, hoist hook blocks must be raised and lowered straight up and straight down, and the wire rope cable wraps around the drum, within the grooving, in one layer. In the course of picking up a load, if the operator side pulls the rope by more than about three degrees from vertical, the wire rope will jump the drum’s grooves.

Once the grooves are jumped, the operator must realize the error and stop using the hoist immediately. To correct the issue, the load must be lowered and the wire rope must be allowed to return it to the correct drum grooves. If the operator continues to use the hoist with the wire rope piled up at one end of the drum, the rope gets pinched and the cable can become damaged. Also in the course of usage, if the cable goes slack and the wire rope jumps over the drum guard, it could get caught between the drum and the shaft, and the wire rope could fail.

The Solution

To prevent this problem, we recommend operator training classes and regular inspection of the unit. Every shift should start with an examination of the wire rope by lowering the hook all the way down. If the rope is damaged, including even one strand broken, stop the process and get the rope replaced. We recommend keeping spare ropes in stock to avoid downtime and always buy OEM Hoist wire ropes. If not, your replacement may be the wrong type, grade, or end fitting.

Hoist Sales, Replacement Parts, Training & Other Services

Need more information on replacement wire ropes or wire rope hoists? Contact us online or give us a call at 800-642-7263. We carry a large selection of hoists and OEM replacement hoist parts as well offer comprehensive services throughout the Mid-Atlantic Region, including New Jersey, the greater New York City metro, the greater Philadelphia metro, Delaware and the eastern shore of Maryland. These services include overhead crane repair, hoist repair, OSHA inspections, load testing, crane and hoist operator training, and fixed ladder inspections.