Considerations When Upgrading a Patented Track System

Andrew T. Litecky

Welcome to The Hoist Guy's Blog, where our resident Hoist Guy, Andrew T. Litecky, shares his knowledge and experience of many years in the overhead material handling industry to discuss crane equipment and system upgrades. What trade offs should you consider when upgrading your patented track system? Read on to learn more from the bridge crane specialists at Shupper-Brickle Equipment.

New Crane Equipment VS Upgrading

“Can we add extra supports to make our 12-Ton patented track system safe for 16 tons?” This question was posed by an experienced engineer for our international manufacturing customer who was facing a challenge to rework the crane system for heavier loads.

He was trying to avoid the purchase of an entirely new patented track crane system. However, a full investigation into upgrading the existing system revealed many trade-offs.

The Bridge Crane System in Question

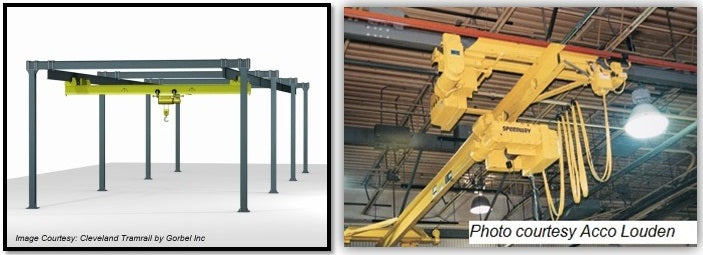

The original system included a 12-Ton underhung bridge crane with two interlocked monorail spurs, all made from patented track. The engineer based his calculations on the additional load and came to the conclusion that adding extra support steel to the runways and spurs could increase the load capacity of the system. However, to correctly calculate this increase, it’s important to consider the factor of wheel load.

More Complete Calculations

Patented track is limited by the equivalent center load and by the maximum per pair wheel load. In this case, Tarca Track made by Cleveland Tramrail has a limit of 10,500 lbs per pair of wheels. If you increase the load from 12 tons to 16 tons, that’s a 33% increase, and it would put the per pair wheel load over the 10,500 lb limit.

The Resolution

To resolve this situation and reuse the existing equipment, we recommended an increase in the number of trolley wheels along with the added steel support. By changing the trolley wheels from 8 to 16, this would prevent the overload conditions on the lower flange of the patented track. However, as the old engineering adage goes, “you never change just one thing”, and in this case adding trolley wheels also meant adding headroom and losing space at the end approaches (since the new trolley wheels take up more room). Unfortunately, a major trade-off of this plan is reduced hook coverage across the entire system.

With this analysis, our customer was able to consider the full costs and benefits of a new system versus an upgrade to the existing crane equipment. It’s important to note that only adding support steel without increasing the number of trolley wheels for this capacity increase, would have resulted in an overloaded system, potentially causing damage or a catastrophic failure.

Crane Sales & Service

Since 1969, Shupper-Brickle Equipment has solved overhead material handling challenges and provided unique industry expertise to our customers. Shupper-Brickle Equipment offers patented track bridge cranes, monorails, and engineering support. Contact our bridge crane specialists for more information on crane sales and services, new equipment and system upgrades.