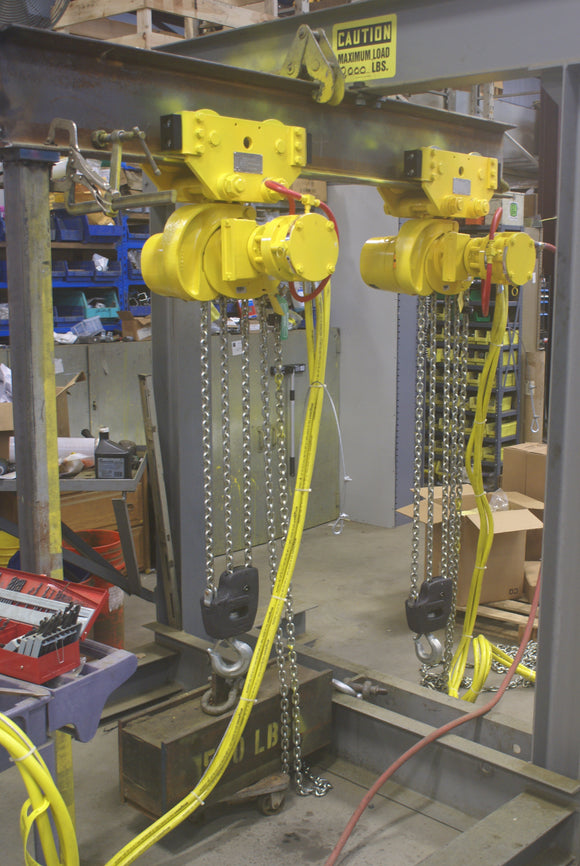

Air Chain Hoists with Dual Redundant Brakes

Shupper-Brickle Equipment combines over 50 years of hoist and crane industry experience with a full-service engineering department to offer customized services and equipment, including a dual brake air hoist. We modify a manufacturer-standard air chain hoist to add a second brake for applications with the highest safety standards. There are many available electric chain hoists with a second brake, but this product is our unique modification to equip air hoists with dual redundant holding brakes.

Benefits of a Dual Brake Air Hoist

Air-chain hoists are built to withstand high duty cycles and challenging environmental conditions offering many benefits for a variety of applications. Adding a second brake can provide even more benefits including:

- Dual Brake Air Hoists are ideal for use under conditions where critical lifts are required and dropping a load is not an option.

- Air motors are sealed against dust, moisture, and corrosive gases, where external air is kept out by internal pressure.

- Air motors will never overheat due to continual air flow through the motor. They perform well in high temperature environments and in high duty cycle applications.

- Spark resistant models are available for hazardous locations, such as chemical and petrochemical industries.

- Precise, variable controls make load placement easy.

- Dual redundant brakes ensure maximum safety by providing a secondary braking system should the primary brake fail.

Upgrade Your Hoist with Shupper-Brickle’s Engineering Services

Our custom engineering services can supply you with an air chain hoist with a dual redundant holding brake for enhanced air hoist safety.

The standard model of this hoist is available in capacities of 1/2-Ton, 1-Ton, 2-Ton, and 3-Ton. The spark-resistant model is available in capacities of 1/2-T, 1-Ton and 2-Tons. Shupper-Brickle can upgrade any of these models with a second brake.

Since 1969, Shupper-Brickle has provided hoists and overhead crane engineering to to the Mid-Atlantic States and worldwide. Learn more about the lifting innovations designed by our engineering department and made by our fabrication team. Contact us for more information or see our white paper for more info on spark resistant models, features of the hoist and basic hoist data. You can also read our blog post on the difference between hoists with a single brake versus a dual braking feature.